Basic Process

-

Treatment temperature: typically in the range of 750–880 °C (lower than Carburizing: 900–950 °C).

-

Diffusion atmosphere: a carbon-rich gas mixture (CO, CH₄, or modified natural gas) combined with NH₃ as the nitrogen source.

-

Diffusion mechanism:

-

Carbon diffuses into the austenite lattice → surface enrichment with carbon.

-

Nitrogen dissociates from NH₃ → atomic nitrogen diffuses simultaneously, partly dissolving in austenite, and partly forming nitrides/carbonitrides (Fe₃(C,N)).

-

-

Quenching: usually oil, water, or high-pressure gas quenching → transforms the C+N enriched austenite surface into supersaturated hard martensite.

Characteristics & Applications

-

Case characteristics:

-

Shallower case depth compared to carburizing (typically 0.1–1.25 mm).

-

High surface hardness (55–62 HRC), with improved tempering resistance.

-

Nitrogen addition enhances wear resistance, fatigue strength, and reduces distortion during quenching.

-

-

Advantages:

-

Shorter processing time compared to carburizing.

-

Minimal dimensional distortion.

-

Effective for low-carbon and low-alloy steels.

-

Lower cost compared to deep carburizing.

-

-

Limitations:

-

Thin case layer, not suitable for components requiring deep wear resistance.

-

More difficult to control case uniformity in complex-shaped parts.

-

-

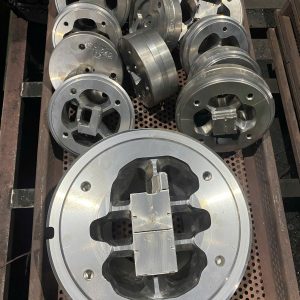

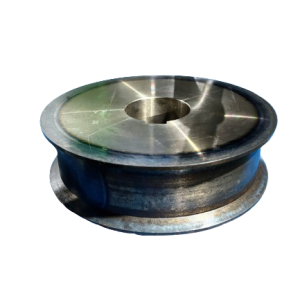

Typical applications:

-

Small gears, shafts, pins, and bolts subjected to fatigue loading.

-

Automotive and motorcycle components (camshafts, piston pins, gears, shafts).

-

Small mechanical tools requiring wear resistance and high fatigue strength.

-

日本語

日本語 English

English 中文 (中国)

中文 (中国)

Đánh giá

Chưa có đánh giá nào.